Lean & Affordable Product Development

A product’s design will evolve dramatically from the initial concept to achieve the functional and performance requirements that were set in the beginning. The nature of the development process, the costs involved and the learning that happens from one iteration to the next are the drivers of this dynamic.

That is why it is so silly to spend unnecessary engineering and design time developing the perfect form that can only be produced with additive manufacturing or production manufacturing processes upfront with the traditional industrial design process. It is the route of big-name industrial design firms, taught in universities around the globe, and is arguably a royal mistake.

It puts form before function, which requires a significant budget and timeline to cross the finish line. The final product design will always be dramatically different after performance testing and especially market testing is flushed through. The traditional industrial design approach traps clients into an expensive process that has a lower probability of success due to the budget and time sinks that it creates.

Additive Manufacturing

The technology has come a long way since we had our own 3D printing shop back in 2011. Materials are arguably 10x better in real-world performance, the alloy and 3D metal Printing technologies are impressive now, and depending on the widget to be made, the entire development cycle can almost be flushed through using additive manufacturing; side-stepping traditional manufacturing processes.

Knowing when and how to leverage this technology is key to avoid the dangerous DFM pitfalls we outlined in our article, The 3 Axioms of DFM.

Manufacturing Costs Dwarf Development Costs

85% of the costs incurred throughout the life of a project happen during production, which is the last phase. However, those costs are dictated by the design concept, engineering, manufacturability, and planning during the first 15% of the project (first phase).

|

Development Phase |

DevSixOne Lean Development |

|

|

Conceptual Design |

3% |

$7.5k |

|

Design Engineering & Testing |

5% |

$12.5k |

|

Pre-Production & Market Testing |

7% |

$17.5k |

|

Production of 14,000 Units |

85% |

$212.5k |

So many times when our own customers learn what it is going to cost to just make 50 of their widget stateside to be functionally tested, they instantly think China. Yet most have no idea that if we followed the traditional industrial design process, it would be 10X depending on complexity. If engineers and designers fulfill their design and engineering purpose, the probability of a project completing successfully skyrockets.

Lean & Affordable Development

We say and lean and affordable product development, but really our approach is sensible and efficient regardless of budget size. Why waste time and money? The goal is to cross the finish line without breaking the bank.

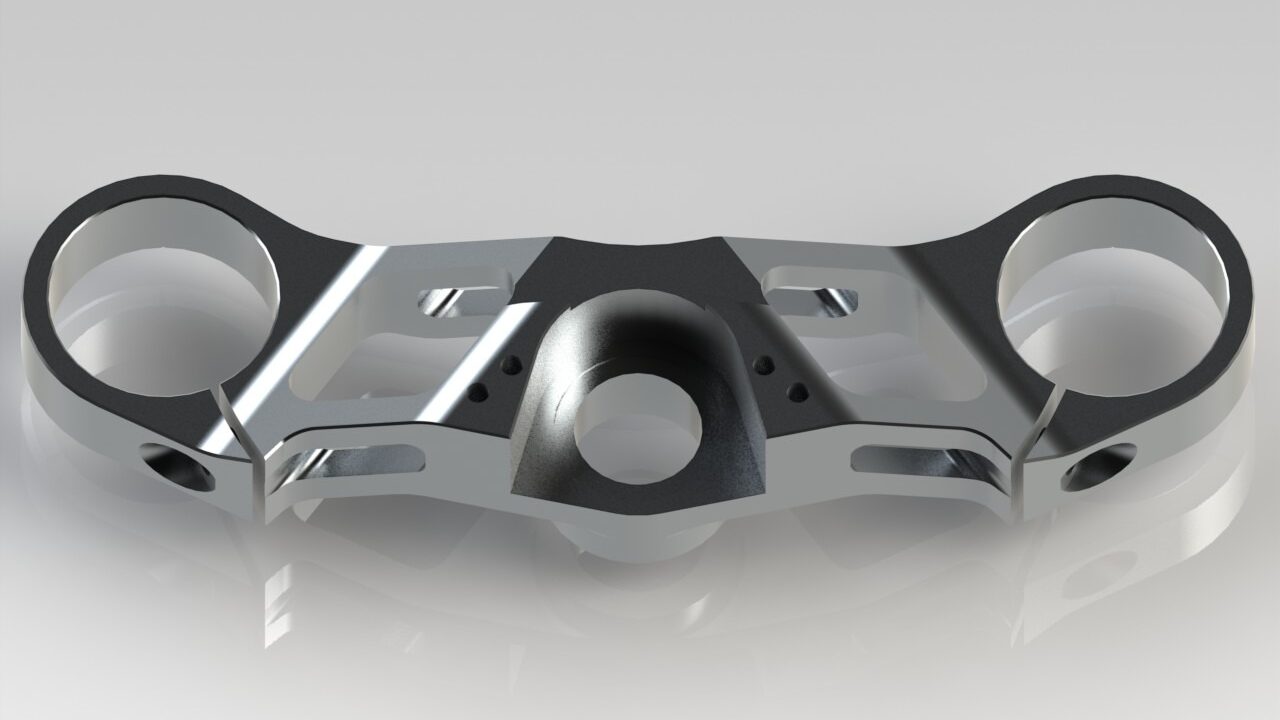

Solve the functional problem first with an eye and reference for the desired aesthetic using economic manufacturing techniques and designs that can be produced using various techniques. Conduct thorough performance testing juxtaposed to the product requirements established upfront, then test the market with a design that is already cost-effective to manufacture and visually close to the ideal vision.

We will often produce two visions for the customer in the concept phase, one that is the sexy end-game and one that will be cost-effective to make and test through the bulk of the development.

How did we learn all this? We’ve felt the pain of the traditional process ourselves so many times over 25 years, whether it was a consumer product, a semiconductor tool mainframe, or the cult classic Tesla Roadster. Living through the pain and frustration of losing unnecessary time, stress, hard work, and money has taught us the valuable lessons that we use to guide our clients.

Classic Example

Let’s say you have a $15k budget to develop your new paperclip idea. The design team you hired provides exactly what you wanted conceptually and it is estimated to cost roughly $.30 each to make 1,000,000 of them. Your plan is to sell 100s of millions once you secure investors. In your business plan, you add 90% for a retail price of $.57 each (30% profit for you, 30% for distributor, and 30% for retail) and the numbers look great and so you start the functional and performance testing phase.

But it costs $10 each to make 1000 of them using additive manufacturing (3D Metal Printing) of titanium and they don’t perform mechanically well due to fatigue and break easy. Rather than test the market with parts that will break easily, you wisely choose CNC machining of homogenous titanium. If you were working with us, a redesign would not be needed, but because you already assumed you would use the 3D Metal Printing process, a redesign is needed. Pricing is roughly the same for CNC machining now, so you spend another $2k and two weeks for redesign and then $10k to make 1000 paperclips with CNC machining and test the market to quickly learn that nobody will pay more than $.20 for the product and the titanium material costs $.17 each at quantities of one million. Now, you are out a total of $27k plus, stuck with a design that can’t scale, and it’s back to the drawing board.

This scenario is why investors won’t consider a project until the market has been tested, the product verified and the true manufacturing, packaging, etc. numbers look great. We all know the TV show Shark Tank and this is exactly what Mark Cuban drills contestants on out the gate. Every successful SharkTank contestant followed our 3 Axioms of DFM from the get-go.

The reason most do not follow the 3 Axioms of DFM is that it usually ends in bad news for the inventor, t hat the once-great idea isn’t feasible because it costs too much to make and impossible to bring the costs down due to the way it was developed from the very beginning.

Please join us for a breakdown and comparison beyond this thought experiment of the development costs of the traditional approach versus our, “Lean and Affordable” approach for one of our projects.

Check Out The Cost Comparison