Design. Build. Learn.

Design & Engineering

Services

Mechanical Engineering

Licensed Professional Engineer, PE

CERTIFICATE NO. M 31341 – CA

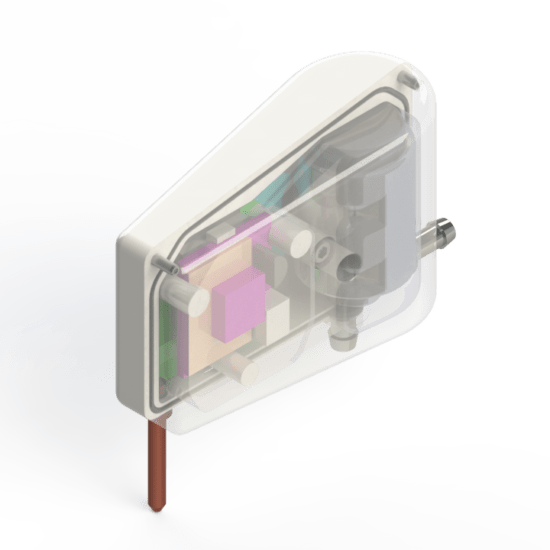

Our product design services are unique in that we get to work quickly to develop a functional prototype that is sexy and meets your performance requirements while being easy to manufacture (profitable).

-

- Industrial Product Design

- Lean & Affordable Product Development

- Develop Prototypes (Scalable)

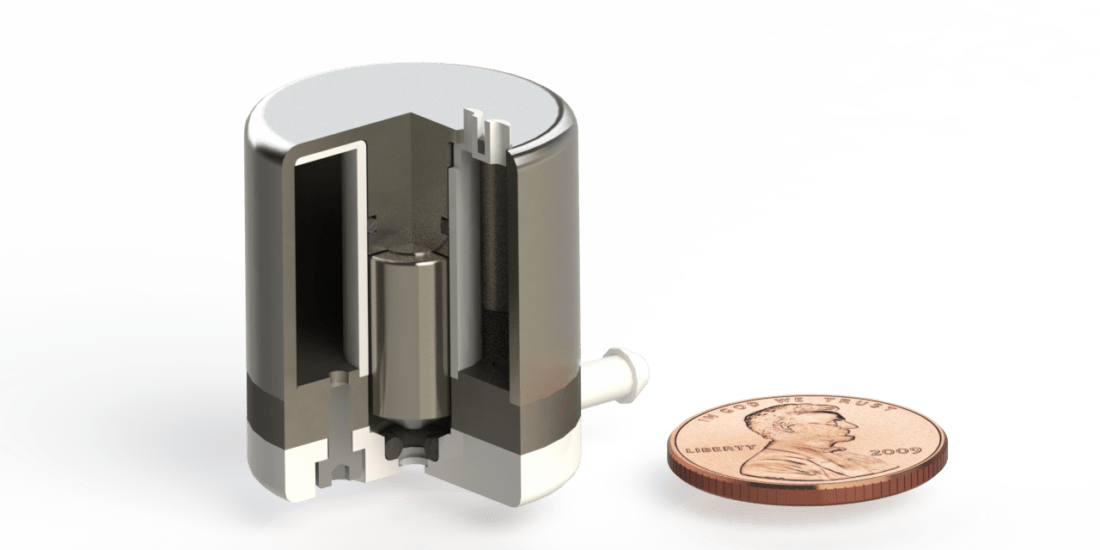

- Mechanical Design & Miniaturization

- Electro-Mechanical Design

- Design for Manufacturability (DFM)

- Smart Assembly Techniques (SAT)

- Pressure Vessel Design per ASME

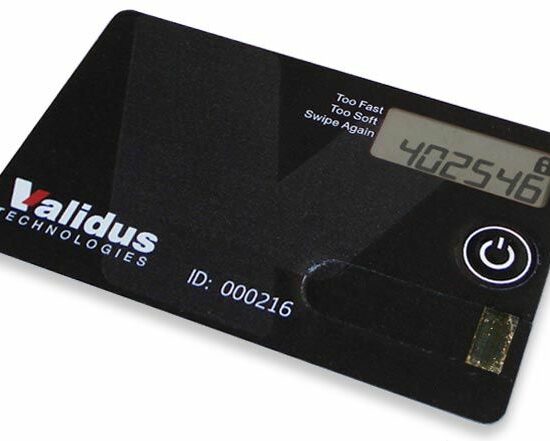

- Flexible Circuits, PCB Assemblies and RF antenna design

Mechanical Engineering is a tip of the spear field with a plethora of sub-fields that range from material science to fluids to automation. We are fearless in taking on new projects and enjoy creating clever solutions. Below is a list of ME services and expertise we offer:

-

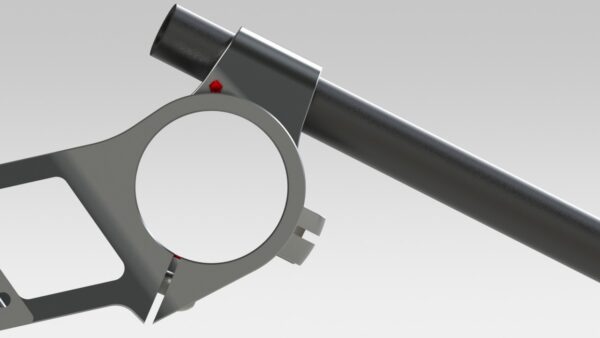

- Mechanical Engineering & Miniature Electro-Mechanical

- Electro-Magnetic Applications (Solenoids)

- Cost-Based Tolerance/Gap Allocation & RSS Analysis

- Reverse Engineering Services

- Broad knowledge of materials, treatments, coatings, plating, and finishes

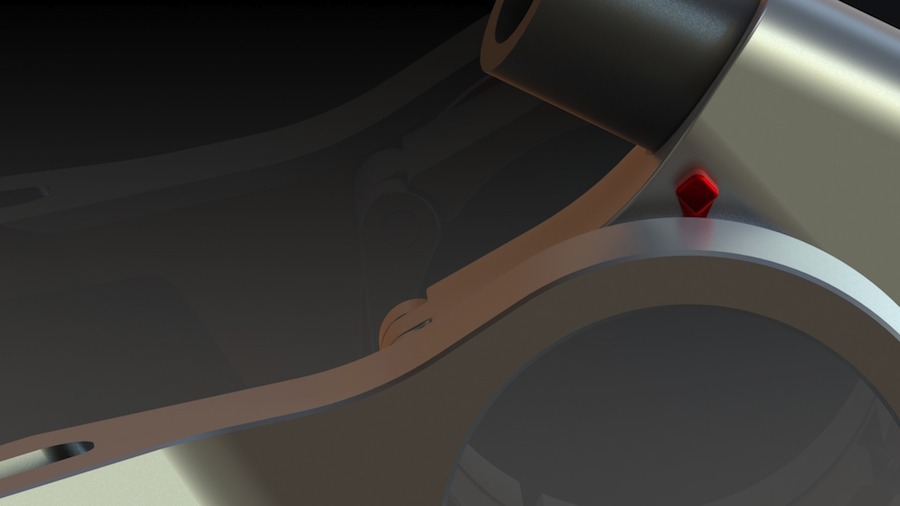

- Finite Element Analysis (FEA) for material stress and deflection

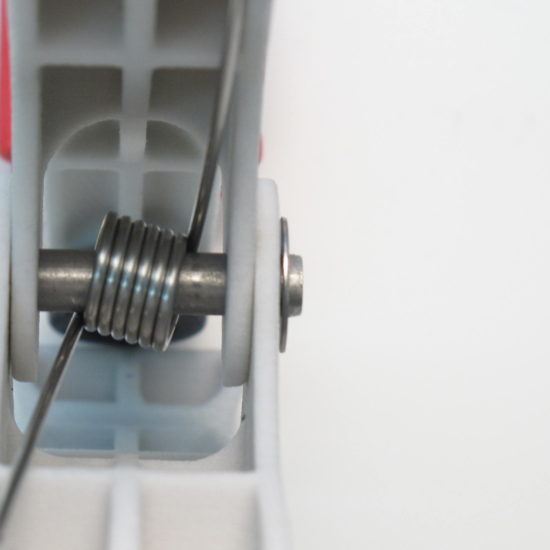

- Motion and Kinematic Analysis

- Professional Manufacturing Drawings & Documentation

- GD&T, ANSI Y14.5-2018 (Geometric Dimension & Tolerancing)

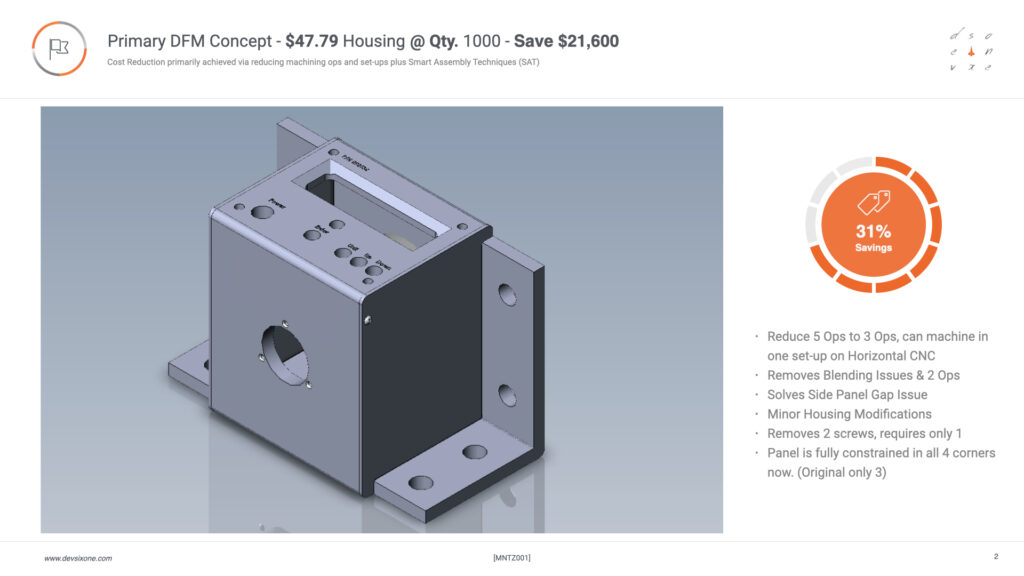

- DFM Design Reviews for quick and easy cost reduction

- Engineering for Shock and Vibration

- Actuator and Control System Engineering

- Electric Vehicle Packaging, clearances and crash testing

- Composites, Epoxies, Tapes, and Rivets

- Chemical/Mechanical Process equipment sizing

- Can be your Engineering Expert Witness in the Court of Law.

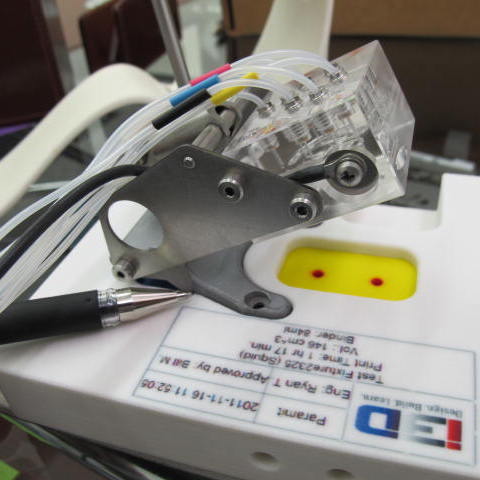

DevSixOne originally started as a 3D printing prototype shop operating within a machine shop. We have the know-how, the resources, and are capable of facilitating the manufacture of prototypes, low-volume pre-production runs, and high-volume production runs for you and at a discount due to our long-standing relationships in the Silicon Valley Manufacturing community. Our Services include:

-

- CNC Machining & CNC Sheet Metal

- Extrusions & Castings

- Additive Manufacturing – 3D Plastic & Metal Printing, SLA

- Wire EDM & Chemical Etching

- Plastic Injection Molding and Reaction Injection Molding

- ESD plastic/foam thermoforming

- Epoxy/Rivet/Tape Composite Construction

- Full Suite of Materials & Heat Treatments

- Specialty Molecular surface treatments

- PCBs (Printed Circuit Boards) & Control Boards

- FCOF (Flip Chip on Flex), Flex Circuits, Wire Bonding

- Lithium-Ion Battery Packs, small and large.

- Manufacturing Liaison with the experience you need to ensure you are never taken advantage of and will educate you along the way.

We save companies big bucks with our Design for Manufacturing (DFM) Reviews that lead to simple changes to designs and assembly strategies. We re-design all DFM cost reduction measures in CAD (Including higher-level assemblies) to ensure that there are no hidden gotchas or interferences first, then we validate the cost savings with our network of manufacturers.

Our 3 Axioms of DFM

When solving tough problems, we strive to provide a frictionless experience for you. We can clearly and effectively communicate complex ideas, articulate progressive strategies, and navigate potential failures in the context of business goals and priorities.

Working with most engineers or smarty-pants types can be unnecessarily difficult and frustrating, however, we are down to earth and easy to work with. Our business structure is set up to offer Silicon Valley experience and expertise at a lower price point than our competitors and our clients have been reaping these benefits for years.

And lastly, our job is to actualize your vision and business goals. Sometimes they are not feasible, other times they may need a dose of reality tweaking, and most of the time they are brilliant and inspiring. In all cases, we will be direct, matter-of-fact, work hard for you, and show you how we can achieve them together.

Get Started

Requirements-Driven

Capture Requirements

We outline and agree upon the conceptual, functional, performance and aesthetic requirements together.

Design for Profitability

Using our requirements and design review process, we develop conceptual prototypes to test feasibility.

Cost Reduction & Scalability

Iterate the solution and test to achieve functional and performance requirements as outlined in step one.