Flash Suppression and Compensator

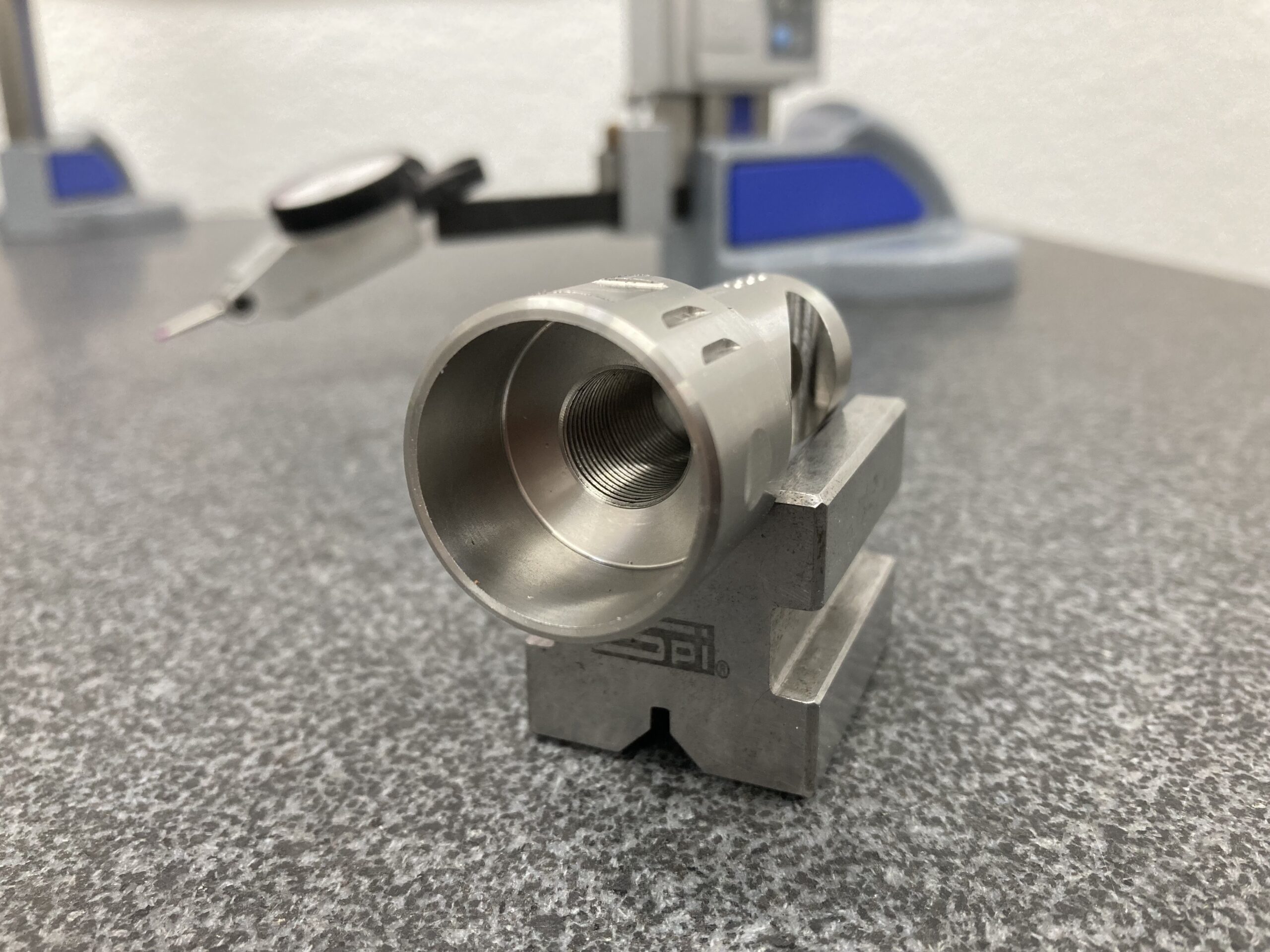

The client’s objective was to quickly engineer a sexy and neutral performing muzzle brake, flash suppressing-compensator for their AR-15 firearm accessories product lines. The most stressed requirement was that it had to look unique and cool. In less than eight weeks from the initial conversation, a quantity of 3000 of these were produced and released into the market.

Again, with zero exposure to a industry and product type, we knocked this out with a single design iteration, achieved the client’s volume manufacturing price target, and facilitated production to ensure they hit their sweet spot sales price on the market, and all 100% made in the USA.

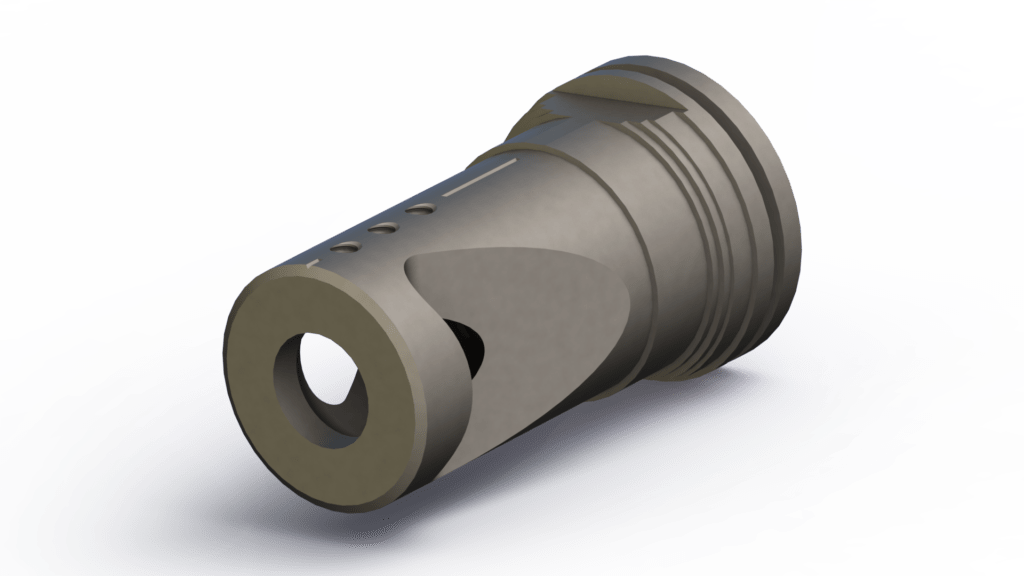

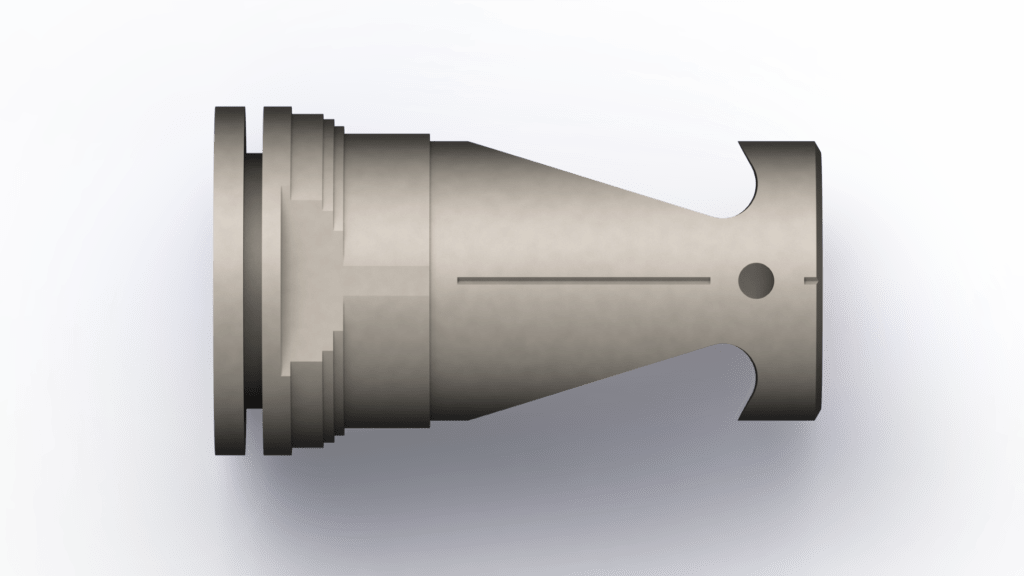

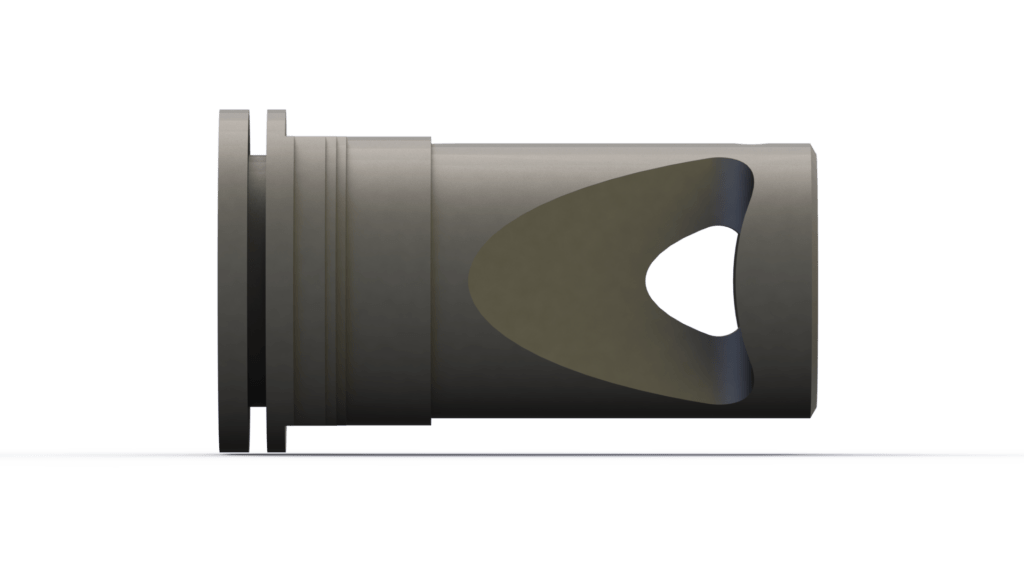

After much research into the industry and competition, it was thought that designing a calibration adjustment for kick-back compensation would be an easy/cool feature while ensuring that all other requirements of marginal flash suppression, kick-back, and lateral release are achieved.

There’re three #4-40 set screws that can can be installed or not, to dial it in for the shooter’s preference. The swoopy-design is not just for aesthetic, it specifically directs flash at an angle from the muzzle to the rear of the shooter so that persons standing to the side of the shooter are not blown out like most muzzle brakes on the market. There’s a lot of non-obvious intrinsic performance in this product that only a firearms aficionado would appreciate.

The client emphasized how important the design must “look cool and unique”. In this industry, most competitors simply make very cost prohibitive features to increase their appeal and then manufacture in China. In a not too distant past, we ran operation of a Silicon Valley CNC machine shop, we know CNC machining better than most machinists on the shop floor, so we used some very cheap and easy tricks of the trade to achieve the visual features that are present in this design, leveraging the wicked material removal time of different processes to ensure the lost-cost manufacturing objective in the USA.