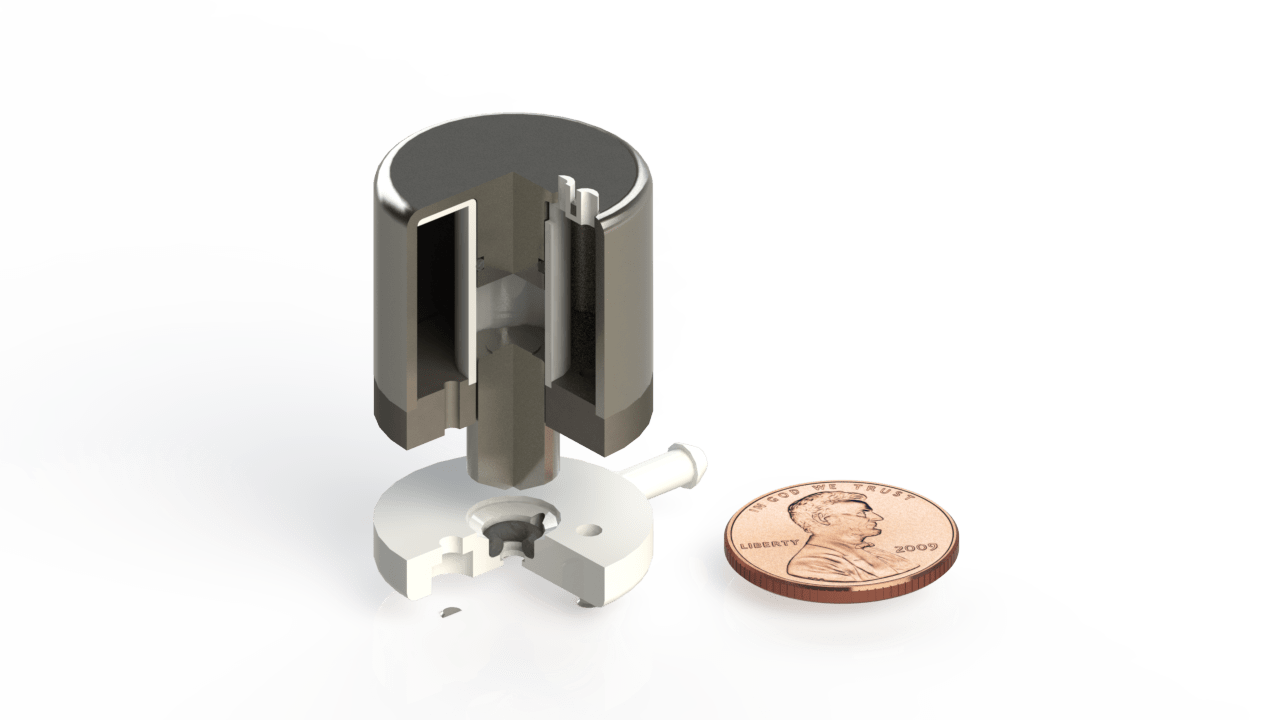

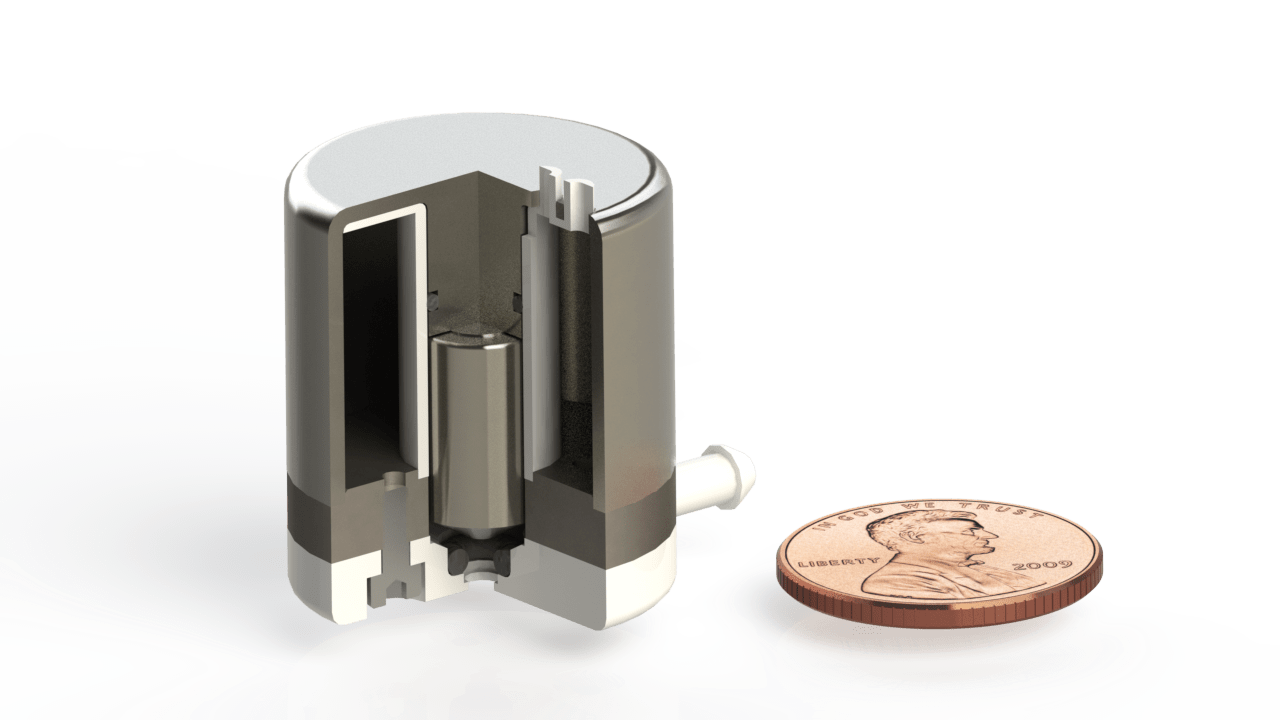

Micro Solenoid Valve

The objective wasn’t just about the miniaturization of solenoid valve technology. It was about achieving high performance while incurring ultra-low power consumption. This (normally closed), direct-acting solenoid valve can open with water pressures up to 45 psi @ .25 watts, hold at .1 watts, and does not have a spring return or diaphragm.

We love this project because it is 100% “engineered” leveraging physics, material science, and savvy DFM (Design for Manufacturability. The nerdy side of us also loves magnets and employing them in clever ways. Solenoid valves are all about electro-magnetism relevant to materials and we had an opportunity to get our minds dirty with first and second-order calculations of electromagnetic performance.

The client arrived with a DIY design and a patent

The client already filed for a patent for their product concept and wished to manufacture it for their product, however, after the initial feasibility study, the first order calculations were showing that the valve would not open or close at pressures above 5 psi and it was a target requirement for the product to be able to open and close consistently at 45psi (typical max pressure in a household) without additional pressure reduction measures; the goal was plug and play.

Clients do not want to hear there idea isn’t going to work, especially one that filed for a patent already and hasn’t had the experience of working with us yet.

This happens more often than one would think. Most folks have great ideas and run into brick walls when it comes time to develop them to meet performance and BOM cost requirements.

So we proposed to pursue the client’s concept and a secondary concept that showed the most promise from basic calculations we performed during the feasibility study.

The client was a champ and agreed to approach both concepts in parallel and fork off the one with the best results.

In traditional D61 fashion, we outlined the requirements for both design paths, testing plans, and dived headfirst into developing a mathematical model.

There are plenty of FEA software packages that claim to spit out the answers for electromagnetic engineering problems, however, we know that the fast track is to build a mathematical model in Excel to achieve the targets, design the product, build asap, test, and learn. The test results will reveal the next steps and we save the customer valuable costs/time along the way.

Cheap Chinese Reference Valve

Lest we not forget, the client and D61 reverse-engineered a Chinese solenoid valve such that we could mathematically model its performance for a third-party reference of cost, size, and functional performance. This step was critical in providing a third-party reference and modeling cross-check to ensure power consumption was on target. For reference, the D61 engineered valve performed at 90% the capacity of the Chinese valve and at half the size.

First Iteration

The first results led us to confirm the customer’s concept would not achieve the performance needed and the newly proposed concept was the way to go. It would be all about engineering an efficient electromagnetic push/pull system, versus BOM cost versus electromagnetic performance of the materials moving forward.

Furthermore, we were lucky. the customer was able to automate winding coils in his garage and had his own 3D printer to flush out early design fitments; we had fun collaborating and working together.

2nd Iteration Baseline Performance Achieved

We were able to show with the second round of engineering, calculations, materials, and tested prototypes that we can achieve the baseline performance and it was all about hitting the high-performance target while testing a couple of hypotheses on varying materials and their electromagnetic performance. In this phase, we learned the most about exactly which materials to pursue next, coil performance versus design, and electromagnetic efficiency relative to various mechanical design features.

3rd Iteration – Nailed It

This project had an incentive and penalty agreement. There was a baseline performance we agreed to target (35 psi, 2nd Iteration). If we did not meet this baseline, we lost 30% of the value of the project and if we hit the ideal target of (45 psi), we received a 30% bonus.

And sure enough, we made it happen, earned the bonus and the customer was thrilled.

Is it for sale yet?

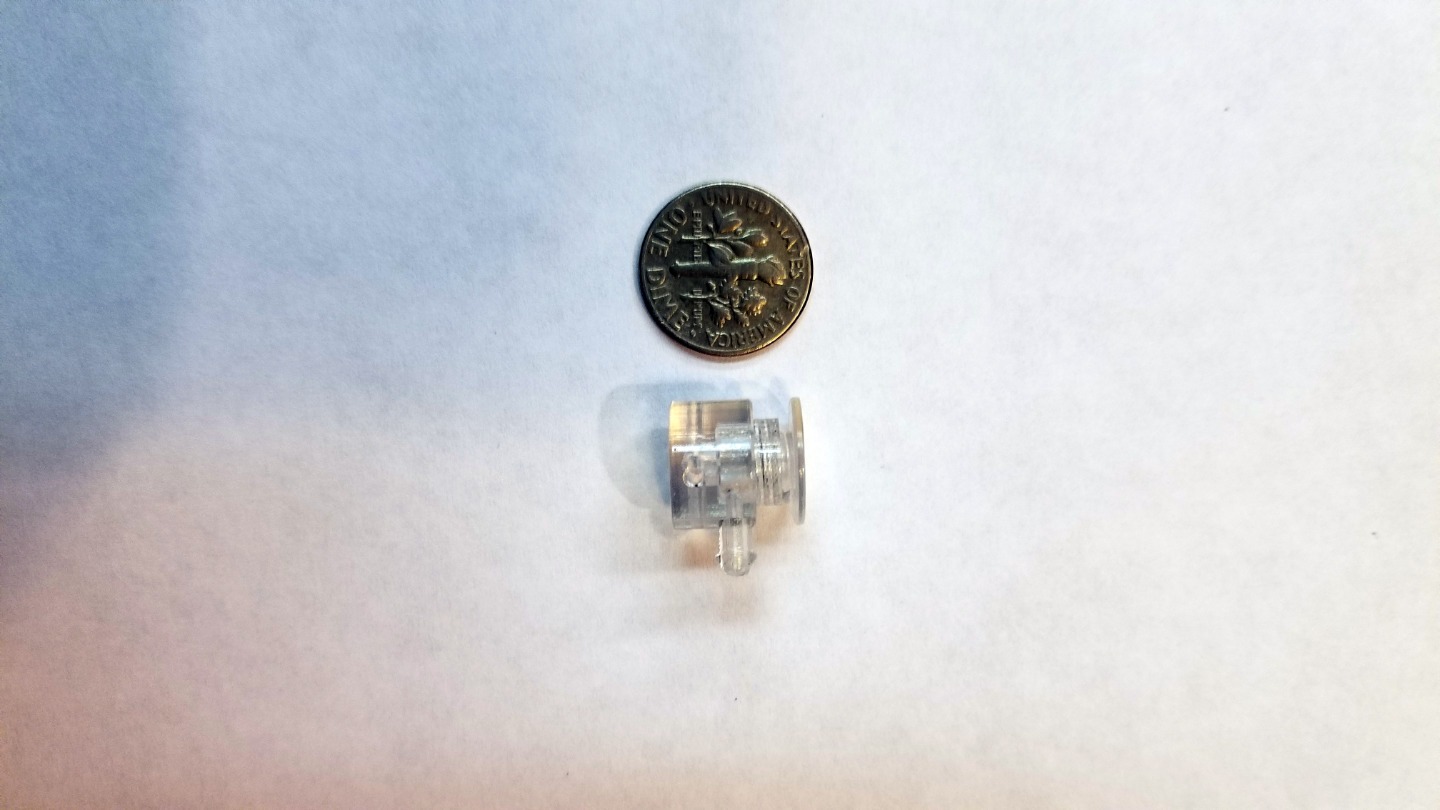

No. This is a sub-component of a larger product that we cannot share with you just yet;) The photo to the right is a 3rd iteration prototype manufactured from an iron alloy, hence a little rust. We did not nickel plate the parts, as the primary goal was to generate the test results to discern final material selection and performance.